Comec RP1000.M Cylinder Head and Block Resurfacing Machine

The RP1000 is a resurfacing machine for cylinder heads and blocks of cars and trucks, as well as for all flat surfaces requiring a finished and accurate mating surface.

All machine parts, like the base, the table, the column and the head are made of widely ribbed cast iron of the best quality, thereby offering highly rigid and sturdy features.

The table feed is operated through a recirculating-ball screw that is extremely precise even at slow feed speeds. A frequency inverter controlling the screw is attached to the motoreducer to offer different speed feed that can be widely adjusted with a potentiometer.

Another inverter adjusts the spindle speed, in order to get the ideal cutting speed at all times and according to the different cutting systems, like abrasive sectors for the grinding of cast iron or aluminium cylinder heads with pre-chambers, the tool for aluminium resurfacing or the CBN-PCD toolholder plate for high-speed resurfacing.

A conveniently located digital display shows the rotation speed.

For an easy and safe use of the machine, all control commands are located on a rotating control panel that can be adjusted to every operator. Moreover, in order to supply an efficient product, the machine's standard equipment includes the rapid movement of the head, an efficient cooling system complete with a settling tank, and a wheel dressing assembly with diamond dresser.

Useful accessories are also available upon request, such as the adjustable set-up fixture for cylinder heads, the V-block mounting kit, the rotating backing pad for the grinding of flywheels, clutch friction plates or brake discs.

Images may show the product equipped with optional accessories

Standard equipment

- Adjustable spindle speed complete with digital read-out

- Adjustable table feed

- Table with recirculating-ball screw

- Fast motorized head feed

- Manual/Continuous/Automatic working modes

- Turning control panel

- Splash and safety guard with policarbonate shield

- Pair of parallel supports with clamps

- Lubricant for slides

- Wrench set

- Instruction manual

ONLY GRINDING VERSION:

- Ø 355mm Grinding wheel complete of segments for cast iron (10 pcs.) and cutting tool

- Cooling plant complete with pump and settling tank

- Grinding wheel dresser

- Emulsifiable liquid

ONLY M VERSION:

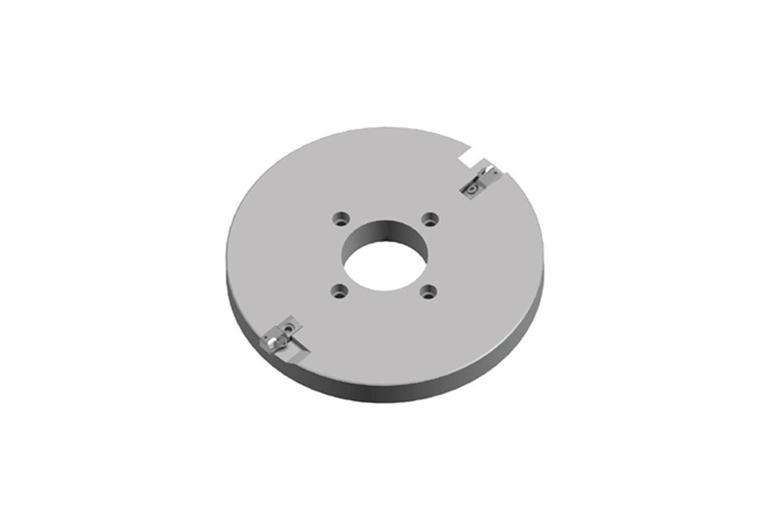

- RP1361 CBN/PCD/ALP Milling plate

- UT1330 1/2”CBN/PCD insert tool holder

- UT1355 1/2” CBN Insert for cast iron

SPECIFICATIONS:

| Table travel | 41.3" /1070 mm |

| Max workpiece length | 35.2"/ 895 mm |

| Max workpiece width | 14" /355 mm |

| Min - Max workpiece height | 4.9"÷ 21.5" /125÷545 mm |

| Useful table surface | 43.3"x 9.1" /1100x230 mm |

| Segmented grinding wheel diameter | 14" / 355 mm |

| Variable head speed rotation | 300÷1500 rpm |

| Variable table travel speed | 0÷59" /0÷1500 mm/min |

| Head motor | 3 hp/4.0 kW (M 2.2 kW) |

| Table motor | 1 hp /0.75 kW |

| Fast head feed motor | .25 hp/ 0.18 kW |

| Coolant pump motor | 0.10 kW |

| Dimensions (LxWxH) | 66"x51"x71"/1680x1140x1850 mm |

| Weight | 3,238 lb. /1015 kg |

Power Requirements: 220 Volt/ 1 Phase/ Full Load AMPS: 17,2A

Shipping information: 71.7" x 39.4" x 98.4"

Shipping weight: 2,640 lbs.

Accessories and Spare Parts

PVA015 Adjustable universal fixture with parallels

PV0015 Adjustable universal fixture with mounting plate

PL000A Motor driven rotary table

RP1361 CBN/PCD/ALP Milling plate dia. 355 mm (14”)

UT0018 Aluminum with Pre-chamber insert tool holder

UT0023 3/8” CBN/PCD insert tool holder

UT0017 Insert tool holder with UT0014

UT0014 Replacement insert for UT0017 (10 pcs)

UT1320 3/8” CBN/PCD insert tool holder

UT1355 1/2” CBN Insert for cast iron

UT1356 1/2” PCD Insert for aluminium

UT1390 ALP insert tool holder for UT1392

UT1392 ALP insert for aluminum with prechambers

UT1330 1/2”CBN/PCD insert tool holder

UT1345 3/8” CBN Insert for cast iron

UT1346 3/8” PCD Insert for aluminium