Comec RP1400.CNC Cylinder Head and Block Resurfacing Machine

The RP1400 CNC is a resurfacing machine for cylinder heads and engine blocks of cars and trucks, as well as for all flat surfaces requiring maximum accuracy of the contact surfaces. The construction technology combines highly innovative solutions, such as the brushless motor for the automatic and precise positioning of the milling cutter plate - that is controlled by the CNC - with tested technologies, like the linear guides and recirculating-ball feed screws. The axes and the rotation speed of the milling cutter are controlled by an inverter. It is possible to monitor the feed speed. The control panel is an industrial touch screen, equipped with a simple and intuitive programme. The RP1400 CNC can be supplied with a milling cutter plate with tool-holder of CBN-PCD with a diameter of 405mm to resurface cast iron or aluminum surfaces. For heads with pre-chambers, you can use a special tool to ensure a perfect finishing.

The RP1400 CNC is defined as the “Smart Resurfacer”, thanks to its laser sensor that scans the cylinder-head surfaces, thus recording their profile and automating milling operations.

Images may show the product equipped with optional accessories

BROCHURE

Standard equipment

| Including standard equipment as follows: |

| MNF100 Single phase version (220V/60Hz/1ph) |

| Ball screw drives on both table and column |

| Table travel by linear railways |

| Brushless motor controlled by CNC |

| Surface scanning system by Laser sensor |

| Touch screen control panel |

| Head positioning by electronic handwheel |

| GL0400 Sliding guide line laser sensor |

| Dia. 405 mm (16”) CBN-PCD milling plate |

| UT1330 1/2” CBN/PCD Toolholder |

| UT1355 1/2" CBN insert for cast iron |

| UT1330 1/2” CBN/PCD Toolholder |

| UT1356 1/2” PCD Insert for aluminium |

| Swing arm control panel |

| Safety guard with sliding doors |

| PV0160 Pair of parallel supports |

| PV0020 Canted clamps with fixing screws (2 pcs.) |

| PV0021 Large clamps (2 pcs.) |

| PV0022 Small clamps (4 pcs.) |

| PVA070 Square head screw M12x90 mm for T-grooves (4 pcs.) |

| PVB070 Square head screw M12x150 mm for T-grooves (4 pcs.) |

| PV0015 Universal fixture for canted Cylinder Head |

| PV1515 V-Block mounting kit |

| Oil for slides (1 lt.) |

| Wrench set |

| Instruction manual |

Specifications

| Table travel | 55" /1400 mm |

| Max working length | 47" /1195 mm |

| Max working width | 15.94" /405 mm |

| Min - Max working height | 7.48"-27.95" /190÷710 mm |

| Useful table surface | 43.3"-13.18"/ 1100x335 mm |

| Milling cutter diameter | 405 mm (16”) |

| Spindle rotation speed | 300÷1200 RPM |

| Variable table feed speed | 0÷1500 mm/min |

| Spindle motor | 2.2kW |

| Table motor | 0.75 kW |

| Feed torque motor | 1.27 Nm |

| Dimensions (LxWxH) | 98.4" x 39.4"x 74.8" /2500x1000x1900 mm |

| Weight | 3,109 lbs./1410 kg |

Power Requirements: 220 Volt/ 1 Phase/ Full Load AMPS: 16,3A

Shipping information: 90.6" x 50.4" x 88.2"

Shipping weight: 3,615 lbs.

Accessories and spare parts

PVA015

Adjustable universal fixture wit parallels

PVA0007

PV0007 Pair of parallel supports H=49mm

PV0015

Adjustable universal fixture with mounting plate

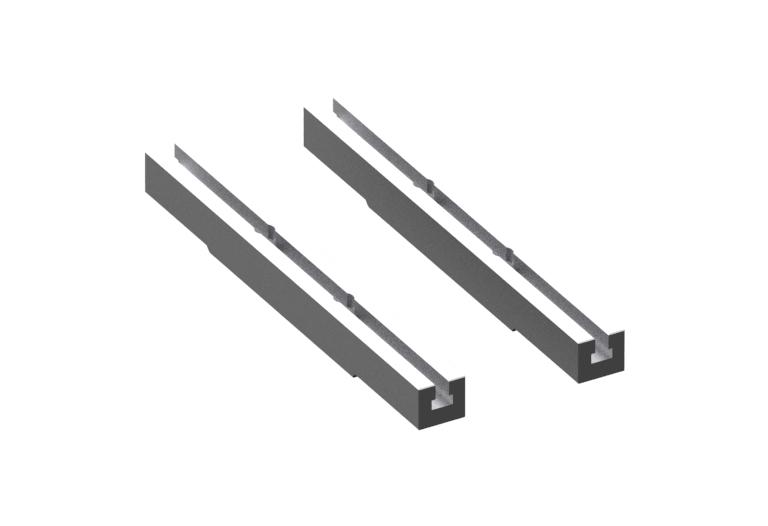

PV0160

Pair of parallel supports

UT1320

3/8” CBN/PCD insert tool holder

UT1355

1/2” CBN Insert for cast iron

UT1356

1/2” PCD Insert for aluminium

UT1390

ALP insert tool holder for UT1392

UT1392

ALP insert for aluminum with prechambers

UT1330

1/2”CBN/PCD insert tool holder

UT1345

3/8” CBN Insert for cast iron

UT1346

3/8” PCD Insert for aluminium

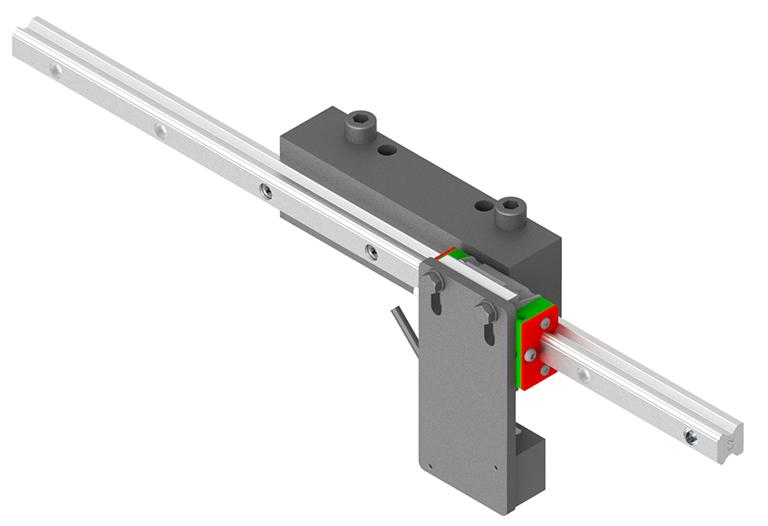

GL0400

Guide line laser sensor