Comec RSM240 Rim Straightening Machine and Lathe

RSM 240 is designed and manufactured to repair by straightening all kind of steel, aluminium and alloy wheels with range diameter between 12" and 24".

The system uses an easy to handle hydraulic cylinder actuated by an hydraulic unit that, conveniently positioned, pushes on the damaged part of the rim taking it back to the original shape. Such operation is made easier with the aid of a wide set of shaped punches that perfectly lean to the different rim profiles. Furthermore the hydraulic cylinder is provided by a pressure regulation system with manometer (PRP100) which allows the adjustment of push force in accordance to the material on work.

RSM 240 moreover is equipped with a lathe unit that allows, after the wheel straightening operation, to remove dents on the edges.

Useful accessories among which the adjustable spindle speed with digital readout (VRV050) or the dial gauge for alignment (CPR150) are available according to every kind of need.

Discover more wheel straightening machines

Images may show the product equipped with optional accessories

Scope:

Standard equipment

- Wheel centering rings

- Gauge

- Angular tip

- Flat tip

- Square tip

- Chisel tip

- Extendedtipholders

- Rim cutting tool

- Wrenchset

- Instruction manual

Specifications

Application range: 13" - 24"

Max working pressure: 140 bar

Max punch force: 3950 Kg

Spindle rotation speed: 80 rpm

Hydraulic unit motor: 0,75 kW

Lathe unit motoreducer: 0,75 kW

Dimensions (LxWxH): 1100x860x1250 mm

Weight: 350 Kg

Accessories and spare parts

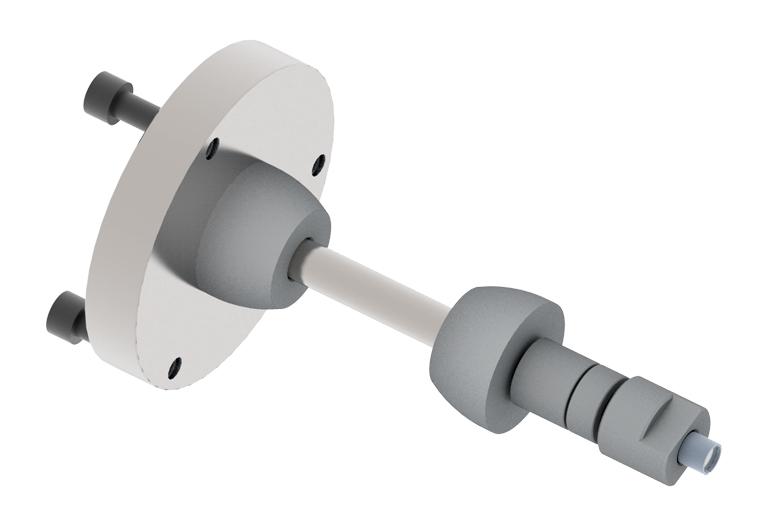

UT0011

Rim insert tool holder

CPR150

Precision dial gauge

KCM100

Motorcycle rims mounting kit

UT0012

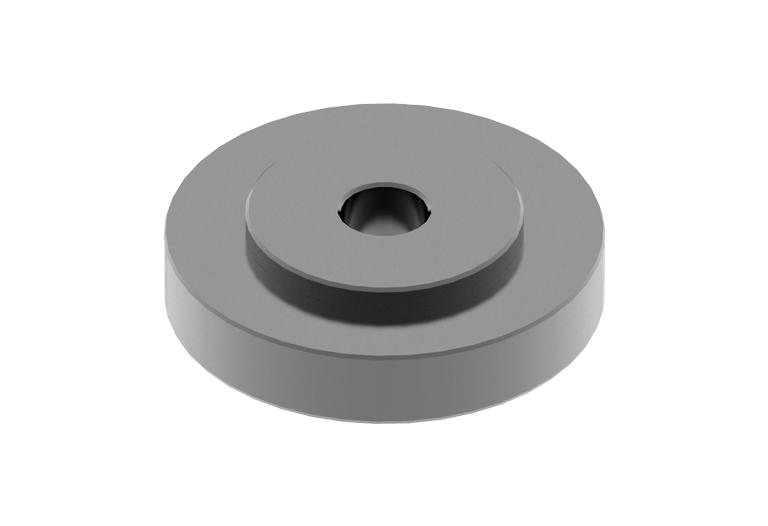

Replacement insert for UT0011, UT5008 and UT5009 (10 pcs.)

PV0096

Vibration dampener band

AC220/XX

Centering rings on demand

PVA070

Set of M12x90 mm T-Bolt screw

DCF010

Set of conical nuts for Ford rims